Just when your device’s tiny components fail, you need expert microsoldering repair that offers unmatched precision and quality. Whether it’s your smartphone, drone, tablet, camera, or handheld console, finding a skilled technician who can handle delicate circuit board repairs ensures your device is restored without costly replacements. With the right service, you’ll experience reliable, long-lasting fixes that bring your electronics back to life. When searching for “microsoldering repair near me” in Canberra and the ACT region, prioritise professionalism and trustworthiness to protect your investment.

The Art and Science of Microsoldering

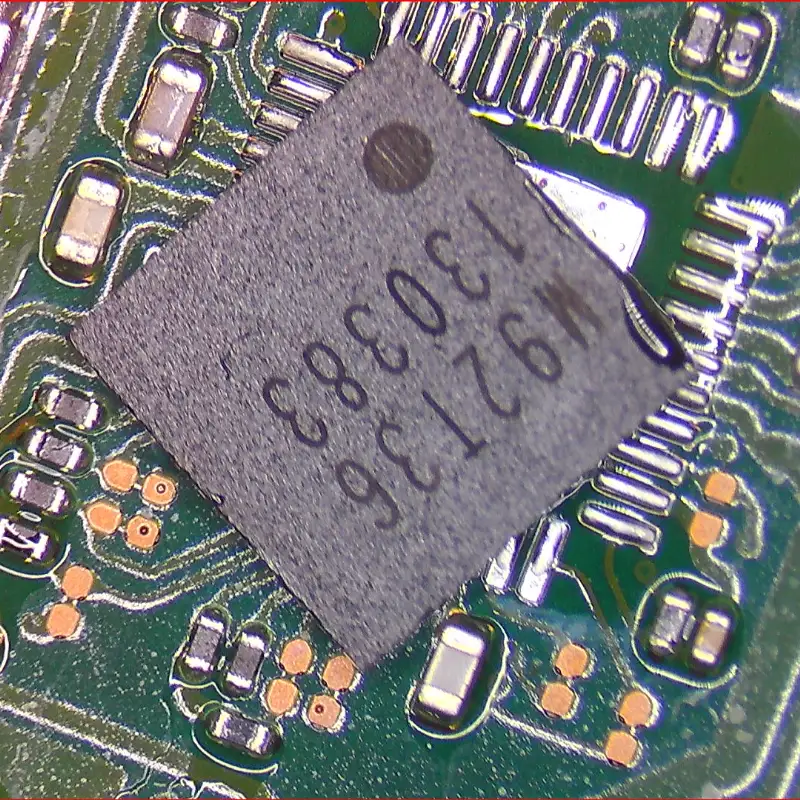

Microsoldering combines steady hands, sharp eyesight, and deep knowledge of electronics into an intricate craft. You work on components often smaller than a millimetre, such as micro-BGA chips or fine PCB traces, where even the slightest slip can cause permanent damage. This blend of art and science allows you to restore devices that seem beyond repair, revealing hidden circuits and delicate connections that power your devices. Mastery here transforms tiny breaks into fully functioning electronics.

Precision Techniques That Make a Difference

Microsoldering demands pinpoint precision accuracy; you often solder joints barely 0.03 mm wide using magnification tools that reveal details invisible to the naked eye. Techniques like hot air reflow, microscopic jump wire bonding, and controlled heat application prevent damage to heat-sensitive components. You’ll find that proper thermal management, alongside steady wrist control, ensures connections are reliable without warping circuit boards. This meticulous approach prevents short circuits and prolongs your device’s lifespan.

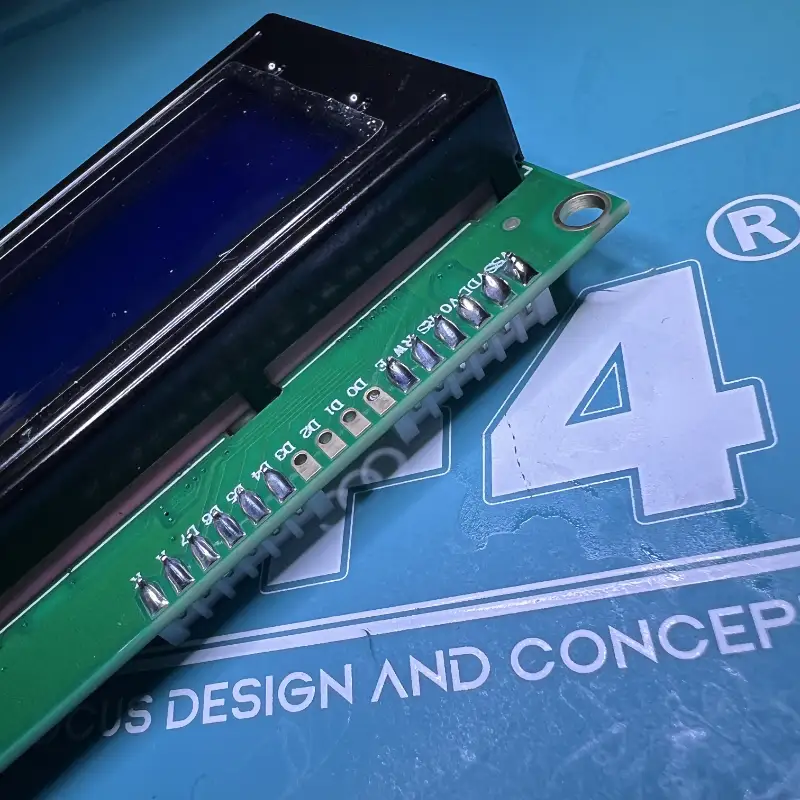

The Tools of the Trade – What Canberra Experts Use

Expert board technicians in Canberra rely on a specialised toolkit tailored for micro-component electronic repairs. You’ll see equipment like temperature-controlled soldering stations with fine-tip irons, board pre-heaters, high-powered trinocular microscopes offering up to 60x magnification, and precision tweezers capable of manipulating components smaller than a grain of rice. Solder paste and solder wire dispensers, grinding pens, flux syringes, and hot air rework stations round out the essentials, allowing you to tackle everything from micro-BGA reballing to delicate trace reconstruction.

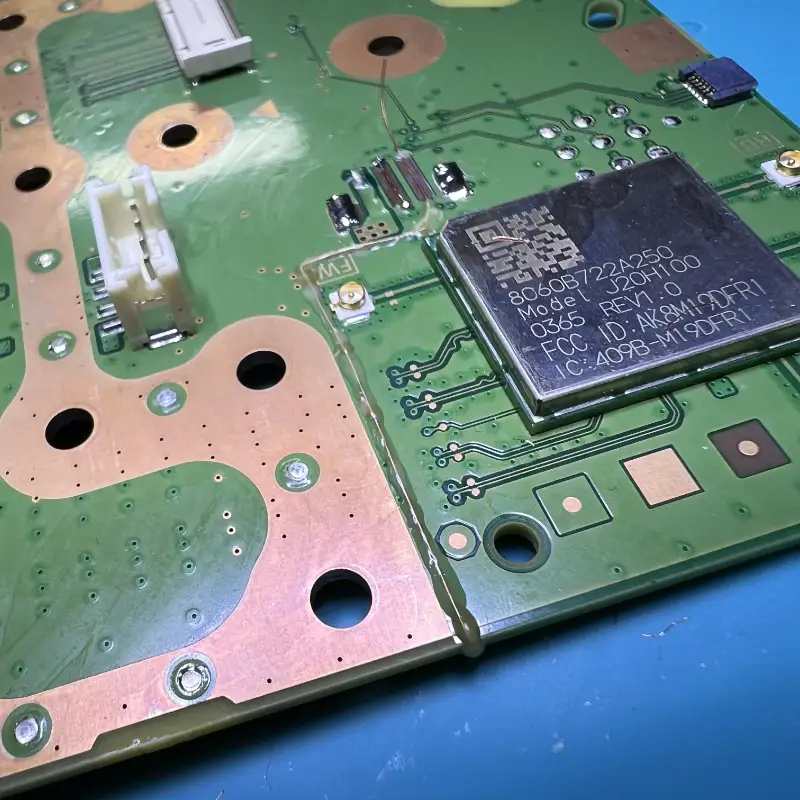

Delving deeper, a typical microsoldering workstation incorporates a high-precision trinocular microscope that lets you detect invisible cracks and lifted pads, essential for diagnosing tough motherboard failures. Controlled hot air rework stations efficiently remove and replace soldered chips without overheating the board. You’ll also find that specialised solder alloys with varying melting points reduce the risk of damaging sensitive integrated circuit (IC) components. Together, these tools empower you to perform complex repairs like rebuilding broken vias or reconnecting microscopic wires that standard repairs miss.

Vital Repair Scenarios: When Microsoldering Shines

Microsoldering steps in where conventional repairs fall short, especially when tiny components fail or delicate circuits are damaged. Whether your smartphone suffered a liquid spill or your game console’s motherboard has cracked traces, this precision technique restores functionality with unmatched accuracy. It handles everything from reconnecting microscopic wires to replacing microchips, ensuring devices with complex circuit boards get fixed rather than replaced. You’ll find microsoldering excels in scenarios that demand steady hands, expert knowledge, and specialised tools, turning what seems like a hopeless repair into a success story.

Recovering from Water Damage: A Lifesaver for Devices

Water damage triggers corrosion and shorts that often disable phones or tablets beyond standard repair. Microsoldering can meticulously clean, replace corroded connectors, and rebuild damaged printed circuit board (PCB) traces, salvaging devices many would discard. You can rely on this skill to restore charging ports, connectors, and micro-BGA components affected by moisture, effectively bringing your water-damaged device back to life without expensive replacements.

Complex Circuit Repairs in Canberra

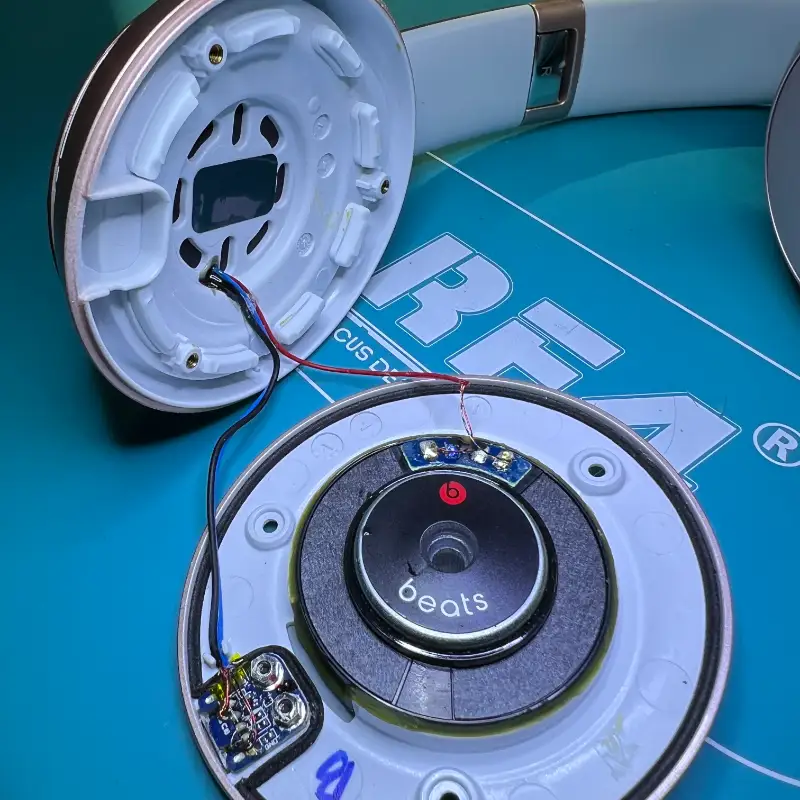

Microsoldering specialises in resolving intricate issues like broken motherboard traces, microchip replacements, and reconnecting surface-mounted components that are smaller than a grain of rice. These repairs require magnification tools and soldering irons with ultra-fine tips to work within confined spaces. For example, restoring a fractured PCB trace on a smartphone logic board, or reballing a micro-BGA chip, demands not only skill but understanding of circuit schematics—a combination that recovers devices that would otherwise be deemed unfixable.

Beyond typical soldering, complex circuit repairs involve trace reconstruction, which can mean laying down conductive epoxy or wiring tiny jumpers to circumvent damaged pathways on multi-layer boards. Experienced technicians use microscopes and temperature-controlled soldering stations to avoid overheating sensitive components. Cases like replacing a charging IC on an iPhone or fixing a micro-BGA chip in a gaming console illustrate how such precision pushes traditional repair boundaries. The outcome is often a device restored to factory-level performance, saving you from costly replacements or data loss.

Identifying Quality Repair Services Near You

Finding a professional microsoldering service in Canberra that delivers precision and reliability involves more than a quick internet search. Focus on shops that specialise in microsoldering, have well-equipped workstations, and technicians certified in electronics repair. Local providers with transparent pricing and clear communication often stand out. Look for specialists handling a broad range of devices—from smartphones to gaming consoles—and those willing to provide detailed diagnostics before any work begins. Quality repair centres typically back up their work with warranties, giving you extra peace of mind.

Essential Criteria to Evaluate Local Shops

Look for Canberra workshops where technicians demonstrate expertise with high-magnification soldering tools and experience repairing micro-BGA chips or PCB trace reconstruction. Shops should offer comprehensive services such as charging port repairs and connector replacements, ideally with a quick turnaround time. Check for the availability of genuine parts and diagnostic equipment that can detect subtle motherboard faults. A clean, organised workspace is often a sign of professionalism and attention to detail, which directly impacts repair success.

Reading Reviews: Why Customer Feedback Matters

Reviews reveal how consistently a shop meets expectations, highlighting the technician’s ability to handle delicate microsoldering jobs without causing collateral damage. Customers often mention turnaround time, cost transparency, and post-repair device performance. Positive testimonials about repairs on tricky components like battery terminals or wiring harnesses provide insight into a repair service’s real capabilities. Negative reviews may warn you about hidden fees or less skilled technicians, helping you avoid costly mistakes.

Customer feedback goes beyond star ratings—detailed accounts of repair outcomes shed light on a technician’s precision and care. For example, a review mentioning a successful PCB trace repair that restored a device’s functionality after water damage demonstrates invaluable skill. Multiple reviews praising a shop’s ability to fix complex connectors or gaming controllers confirm consistent expertise. These narratives can guide your choice by showing which services deliver durable results, superior customer support, and fair pricing, especially in a field where microscopic errors can mean a failed repair.

Cost-Effectiveness of Microsoldering Repairs

Microsoldering repairs offer a highly cost-effective solution for extending the life of your electronics by precisely targeting damaged components rather than replacing entire devices. With repair costs often ranging from a fraction of what a new device would cost, you can save hundreds of dollars by fixing connectors, charging ports, or micro-BGA chips. This focused approach also reduces waste and downtime, allowing you to get back to using your smartphone, game console, or other gadgets quickly and affordably.

Balancing Repair Costs vs. Replacement Pricing

You’ll find microsoldering repairs generally cost between $50 and $250 depending on the issue, compared to $500 or more for replacement devices like smartphones or gaming consoles. Even complex board repairs rarely exceed a quarter of the price of brand-new equipment, making microsoldering a practical middle ground. Consider the device’s resale value and your budget; often, investing in repair preserves original hardware quality and avoids the higher price of full replacement.

Long-Term Benefits of Choosing Repair Over Replacement

Choosing microsoldering repair extends your device’s lifespan without sacrificing performance, saving you money over repeated replacements. Stable repairs prevent recurring problems and maintain your device’s original functionality, which is especially important for costly or vintage electronics where replacements might not even be available. This approach helps keep your devices reliable while reducing electronic waste significantly.

Expanding on the long-term benefits, microsoldering not only restores your device but often improves its durability by reinforcing damaged connections. For instance, repairing a battery terminal on a vintage radio can preserve its original sound quality for years, a value replacement models can’t match. Lower environmental impact and reduced annual spending on electronics further emphasise why microsoldering repair outshines outright replacement, saving you money and hassle over time.

Real Customer Experiences: Transformative Repairs

Countless Canberra customers have witnessed their broken devices return to life after expert microsoldering repairs. Whether reviving a smartphone with water damage, restoring vintage radios, or fixing a game controller’s joystick, these precise repairs have transformed what seemed irreparable. Your device can be next—many have saved hundreds of dollars by choosing skilled microsoldering services focused on quality and attention to detail.

Success Stories of Restoration

One Canberra customer brought in a water-damaged smartphone that multiple ACT shops had deemed hopeless. After expertly repairing corroded micro-BGA chips and resoldering fragile connectors, the device powered on flawlessly. Another local gamer’s joystick, failing due to damaged PCB traces, was reconstructed with precision, restoring full functionality. These success stories showcase how expert microsoldering breathes new life into your most needed tech.

Lessons Learned: The Value of Expert Assistance

Many clients initially underestimated the complexity of microsoldering repairs. Attempting DIY fixes or trusting inexperienced technicians often led to worsened damage or incomplete repairs. Experience showed that professional assistance with specialised tools and steady hands ensures precision and durability, reducing the risk of recurring problems and costly replacements down the line.

Diving deeper, you realise that microsoldering demands not just steady hands but a detailed understanding of circuit design and component sensitivity. Professionals bring years of focused training, supported by microscopes and heat-controlled soldering irons, to navigate tiny components without collateral damage. This expertise prevents common pitfalls like cold solder joints or overheating, which can further degrade your device’s performance. The value of expert assistance lies in dramatically improving repair success rates and extending your device’s lifespan, giving you both peace of mind and better return on your investment.

Ready to Restore Your Devices with Expert Microsoldering?

Ready to find expert microsoldering repair near you? Canberra residents trust Seki Gadgets for professional electronics restoration. Whether you need circuit board repair, water damage recovery, or precision component replacement, our local ACT expertise ensures your devices receive the expert care they deserve.

Visit our comprehensive microsoldering services page to learn more about our capabilities, or contact us today for immediate assistance with your electronics repair needs in Canberra.

FAQ

What types of devices can be repaired using microsoldering?

Microsoldering is used to repair a wide range of electronic devices, including smartphones, tablets, game consoles, drones, headphones, car key fobs, and even vintage radios. This technique allows technicians to fix tiny components and connections on circuit boards that traditional repair methods can’t handle.

How does microsoldering differ from regular soldering?

Microsoldering involves working on extremely small and delicate electronic components using specialised tools and magnification. Regular soldering typically involves larger components and less precise work. Microsoldering requires steady hands, advanced skills, and careful attention to detail to avoid damaging sensitive parts.

What are some common repairs that microsoldering can fix?

Common microsoldering repairs include fixing broken connectors, charging ports, micro-BGA soldering, repairing traces on printed circuit boards (PCBs), replacing battery terminals, resoldering loose wires, and restoring damaged switches or joysticks on gaming controllers.

How can I find a reliable local microsoldering repair service?

To find a trustworthy microsoldering repair service near you, look for repair shops with positive customer reviews, experienced technicians, and a track record of successful microsoldering repairs. It helps to choose shops that clearly explain their process, provide quotes upfront, and specialise in repairing your specific type of device.

Is microsoldering repair cost-effective compared to replacing a device?

Yes, microsoldering repair is often far more affordable than buying a new device. Since it restores the original components and functionality, it extends the device’s lifespan without the need for a full replacement. This makes it a smart option for repairing high-value gadgets or devices with sentimental value.

How do I find the best microsoldering repair near me in Canberra?

Look for established ACT repair specialists with proven microsoldering experience, professional-grade equipment, and positive reviews from local Canberra customers. Check for proper workshop facilities, transparent pricing, and comprehensive warranties. Seki Gadgets meets all these criteria as Canberra’s trusted microsoldering experts, serving the ACT region with precision electronics repair.